Why replace my existing lighting?

Until recently, little has changed within the carwash lighting industry. For years, metal halide lamps have been the standard. Major advancements in LED technology, combined with innovative fixture designs, have made car wash lighting worth getting excited about.

Old, inefficient lighting consumes a large chunk of many sites’ utility bills, maintenance budgets, and carbon footprints. In the past, these high costs were necessary to keep the operation running. This is no longer the case, as the majority of these costs can be eliminated by using efficient LED lighting technology.

Cost savings are not the only reason to replace old lighting. Modern LED lighting produces a brighter and more appealing bay or tunnel, resulting in a happier and safer customer. Customers will also appreciate that your carwash is “going green” by using LED technology.

What are LEDs? How do they work?

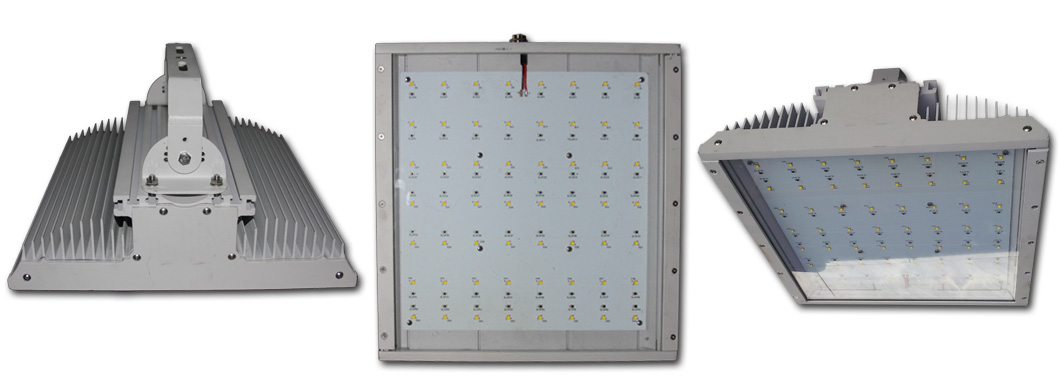

Light emitting diodes (LEDs) produce light more efficiently than traditional lighting sources. An LED is a semiconductor chip that emits photons (light) when conducting current. The technology for LEDs has been around since the 1960s, however, only recently have LEDs been made that produce acceptable levels of illumination for general purpose lighting.

Another substantial benefit of LEDs is that they emit light in a specific direction, reducing the need for diffusers or reflectors that can trap light and resultantly waste energy. With other types of lighting, the light must be redirected or reflected and more than half of the light may never leave the fixture. Conventional light bulbs waste a majority of their energy as heat while LEDs maintain a remarkably low temperature.

Why use LEDs?

Energy Consumption

The most important benefit of LED lighting is the dramatically reduced energy consumption compared to traditional lighting technologies (i.e. HID, fluorescent, etc.). In most cases, energy use is cut by 60-70 percent, which translates into huge savings when the utility bill arrives.

Long Lifetime

Customers can expect quality LED products to last for over 50,000 hours. That is over 10 years at 12 hours/day. LEDs don’t “burn out” like typical lighting solutions, but rather slowly fade over time. By comparison, a metal halide bulb will emit less than 50% of its initial light output after 6,000-10,000 hours.

Maintenance Costs

Additional savings come from reduced maintenance and upkeep. LED products are virtually maintenance free throughout their lifetime. A metal halide fixture would require 5 or 6 bulb changes and 1 or 2 ballast changes over the LED fixture’s 10-year lifetime.

Light Color

LEDs are versatile due to their ability to emit light at nearly all color temperatures (i.e. “warm white,” “cool white,” etc.). Bays and tunnels look brighter and wet cars appear clean and crisp.

Cooler Lens Temperatures

With older, high-intensity discharge fixtures (i.e. metal halide), heat from the bulb builds up within the fixture and lens. This eventually “bakes” residue from the car wash environment onto the hot lens, leading to a significant amount of light depreciation, and an increase in needed upkeep. This problem will not occur with LED products, which are always cool to the touch.

Important factors to consider when choosing LED lighting for carwashes:

Choose a product that is UL Wet Listed and waterproof.

UL Wet Location certification is the premier global test for lighting products to be used outdoors and in other wet locations. They are intended for use in locations subject to saturation/contact with water or other liquids, or products that will be exposed to climatic conditions.

Be sure the product is 100 percent waterproof and not just rain-tight or weather-tight as many canopy fixtures and wall-packs are not designed to operate in these conditions.

Check the products’ chemical compatibility.

Be sure to ensure the lens and overall fixture can withstand the harsh wash environment. Most products are not made to handle the vast array of chemicals seen in carwashes.